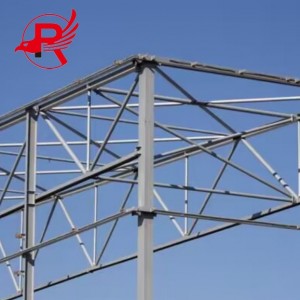

Tilpasset prefabrikert stålkonstruksjon, lager/verksted for industriell konstruksjon

Stålrammehus er en type huskonstruksjon. Stålkonstruksjonshus refererer til boligbygg som bruker stål som bærende bjelker og søyler. Egenskapene er:

Ved å utnytte stålets høye styrke, kan designet ta i bruk en stor fagplanløsning, slik at bygningsplanene kan være rimelig adskilte, fleksible og praktiske, og skape en åpen planløsning.

*Send e-posten til[e-postbeskyttet]for å få et tilbud på prosjektene dine

| Materialliste | |

| Prosjekt | |

| Størrelse | I henhold til kundens behov |

| Hovedramme i stålkonstruksjon | |

| Søyle | Q235B, Q355B sveiset H-profilstål |

| Bjelke | Q235B, Q355B sveiset H-profilstål |

| Sekundær stålkonstruksjonsramme | |

| Ås | Q235B C- og Z-stål |

| Knestøtte | Q235B C- og Z-stål |

| Slipsrør | Q235B sirkulært stålrør |

| Stag | Q235B Rundstang |

| Vertikal og horisontal støtte | Q235B Vinkelstål, rundstang eller stålrør |

PRODUKTPRODUKSJONSPROSESS

FORDEL

Tilstrekkelig stivhet

Stivhet refererer til et stålelements evne til å motstå deformasjon. Hvis stålelementet utsettes for overdreven deformasjon etter å ha blitt belastet, vil det ikke fungere ordentlig selv om det ikke har blitt skadet. Derforstålkonstruksjonmå ha tilstrekkelig stivhet, det vil si at stivhetsbrudd ikke er tillatt. Stivhetskravene er forskjellige for ulike typer komponenter, og relevante standarder og spesifikasjoner bør konsulteres ved påføring.

Stabilitet

Stabilitet refererer til en stålkomponents evne til å opprettholde sin opprinnelige likevektsform (tilstand) under påvirkning av en ytre kraft.

Tap av stabilitet er fenomenet der stålelementet plutselig endrer sin opprinnelige likevektsform når trykket øker til en viss grad, noe som kalles ustabilitet. Noen komprimerte tynnveggede elementer kan også plutselig endre sin opprinnelige likevektsform og bli ustabile. Derfor bør det kreves at disse stålkomponentene har evnen til å opprettholde sin opprinnelige likevektsform, det vil si at de har tilstrekkelig stabilitet til å sikre at de ikke blir ustabile og skadet under de spesifiserte bruksforholdene.

Trykkstangens ustabilitet oppstår vanligvis plutselig og er svært ødeleggende, så trykkstangen må ha tilstrekkelig stabilitet.

Kort sagt, for å sikre sikker og pålitelig drift av stålelementer, må elementene ha tilstrekkelig bæreevne, det vil si ha tilstrekkelig styrke, stivhet og stabilitet, som er de tre grunnleggende kravene for å sikre sikker drift av komponentene.

Metallfabrikasjon er produksjonen av metallkonstruksjoner ved å skjære, bøye og montere. Det er en verdiskapende prosess som involverer produksjon av maskiner, deler og strukturer fra ulike råvarer.

Metallfabrikasjon starter vanligvis med tegninger med presise dimensjoner og spesifikasjoner. Fabrikasjonsverksteder er ansatt av entreprenører, OEM-er og VAR-er. Typiske prosjekter inkluderer løse deler, strukturelle rammeverk for bygninger og tungt utstyr, samt trapper og rekkverk.

Kvaliteten på konstruksjonsstål

Det finnes mange forskjellige valg når det gjelder konstruksjonsstål. Jo lavere karboninnhold i stålet som velges, avgjør hvor enkelt det er å sveise. Lavere karboninnhold tilsvarer en raskere produksjonshastighet på byggeprosjekter, men det kan også gjøre materialet vanskeligere å jobbe med. FAMOUS kan tilby konstruksjonsstålløsninger som både er effektivt laget og svært effektive. Vi vil jobbe for deg for å bestemme den perfekte typen konstruksjonsstål for prosjektet ditt. Prosessene som brukes til å designe konstruksjonsstål kan endre kostnadene. Imidlertid er konstruksjonsstål et kostnadseffektivt materiale når det brukes riktig. Stål er et utmerket, svært bærekraftig materiale, men det er langt mer effektivt i hendene på erfarne og velutdannede ingeniører som forstår dets egenskaper og potensielle fordeler. Totalt sett har stål et stort antall fordeler for entreprenører og andre som har til hensikt å bruke det til industrielle applikasjoner. Eksperter har funnet ut at selv forsterkning av eldre bygninger med nye sveiseprosesser kan forbedre bygningens styrke betydelig. Se for deg fordelene ved å bruke fagmessig sveiset konstruksjonsstål fra starten av for byggeprosjektet ditt. Kontakt deretter FAMOUS for alle dine sveise- og fabrikasjonsbehov for konstruksjonsstål.

INNSKUDD

StålkonstruksjonsfabrikkIngeniørfag er en konstruksjon hovedsakelig laget av stål. Den består hovedsakelig av stålbjelker, stålsøyler, stålfagverk og andre komponenter laget av stål og stålplater. Hver komponent eller komponent er vanligvis forbundet med sveiser, bolter eller nagler. En av hovedtypene bygningskonstruksjoner. På grunn av sin lette vekt og enkle konstruksjon er den mye brukt i store fabrikker, broer, arenaer, superhøyhus og andre felt.

PRODUKTINSPEKSJON

1. Materialtesting av stål

Stål er det grunnleggende materialet iPrefabrikert stålkonstruksjoningeniørfag, og kvaliteten på materialet påvirker direkte sikkerheten og holdbarheten til stålkonstruksjonsprosjektering. Derfor er testing av stålmaterialet den primære oppgaven ved testing av stålkonstruksjoner. Materialtesting av stål omfatter hovedsakelig følgende to aspekter:

1. Testing av mekaniske egenskaper: inkludert testing av strekkfasthet, flytegrense, forlengelse og andre indikatorer for å evaluere stålets bæreevne og sikkerhetsytelse.

2. Analyse av kjemisk sammensetning: Ved å analysere den kjemiske sammensetningen av stål kan vi forstå korrosjonsmotstanden, sveisebarheten og andre mekaniske egenskaper til stål for å evaluere kvaliteten og anvendelsesområdet til stål.

2. Inspeksjon av stålkonstruksjonsforbindelser

Stålkonstruksjonsforbindelser er en viktig del av stålkonstruksjonsprosjekteringen. Kvaliteten på forbindelsen påvirker direkte sikkerheten og stabiliteten til hele stålkonstruksjonsprosjektet. Inspeksjon av stålkonstruksjonsforbindelser omfatter hovedsakelig følgende to aspekter:

1. Inspeksjon av sveisekvalitet: inkludert inspeksjon av sveisens utseende, interne defekter og andre indikatorer for å vurdere om sveisekvaliteten oppfyller spesifikasjonskravene.

2. Deteksjon av høyfaste boltforbindelser: Høyfaste bolter er en av de vanligste forbindelsesmetodene i stålkonstruksjonsforbindelser. Testing av forbindelseskvaliteten og tilstrammingsgraden kan sikre forbindelsens stabilitet og sikkerhet.

3. Dimensjons- og flathetsinspeksjon av stålkonstruksjonskomponenter

Størrelsen og flatheten til stålkonstruksjonskomponenter påvirker direkte installasjonsnøyaktigheten og ytelsen til stålkonstruksjonsprosjekter. Størrelses- og flathetsinspeksjonen av stålkonstruksjonskomponenter omfatter hovedsakelig følgende to aspekter:

1. Inspeksjon av komponentstørrelse: Inkluderer inspeksjon av lengde, bredde, høyde, diagonal og andre indikatorer på komponenten for å vurdere om komponentens størrelse oppfyller designkravene.

2. Planhetsdeteksjon: Ved å måle flatheten og konkaviteten på overflaten til komponenten, brukes den til å evaluere komponentens kvalitet og installasjonsnøyaktighet.

4. Inspeksjon av korrosjons- og brannsikkert belegg

Antikorrosjons- og brannhemmende belegg er et viktig beskyttelsestiltak for stålkonstruksjonsprosjekter, og spiller en viktig rolle i å forhindre korrosjon, branner og andre ulykker i stålkonstruksjoner. Testing av antikorrosjons- og brannhemmende belegg omfatter hovedsakelig følgende to aspekter:

1. Inspeksjon av korrosjonsbelegg: Kontroller hovedsakelig tykkelsen, ensartetheten, vedheften og andre indikatorer på korrosjonsbelegget for å evaluere kvaliteten og den beskyttende effekten av korrosjonsbelegget.

2. Inspeksjon av brannhemmende belegg: Kontroller hovedsakelig tykkelsen, ensartetheten, brannmotstanden og andre indikatorer på det brannhemmende belegget for å evaluere kvaliteten og den beskyttende effekten av det brannhemmende belegget.

Kort sagt, inspeksjon av stålkonstruksjoner er et viktig middel for å sikre sikkerheten og holdbarheten til stålkonstruksjonsprosjekter, og er av stor betydning for å sikre sikkerheten til menneskers liv og eiendom.

PROSJEKT

Vårt firma eksporterer ofte stålkonstruksjonsprodukter til Amerika og sørøstasiatiske land. Vi deltok i et av prosjektene i Amerika med et totalt areal på omtrent 543 000 kvadratmeter og en total bruk av omtrent 20 000 tonn stål. Etter at prosjektet er fullført, vil det bli et stålkonstruksjonskompleks som integrerer produksjon, bolig, kontor, utdanning og turisme.

SØKNAD

Når det gjelder plassutnyttelse,Stålkonstruksjonsverkstedhar et lite tverrsnitt, noe som kan øke bygningens effektive areal med omtrent 8 % sammenlignet med armert betongkonstruksjon. Vi kan dra nytte av stålets høye styrke og bruke et søylenett med store felt for å gjøre bygningsplansegmenteringen fleksibel, noe som ikke bare gir arkitekter handlingsrom i design, men også gir brukerne muligheten til å endre strukturen i henhold til ulike bruksområder.

EMBALLASJE OG FRAKT

PakkingStålkonstruksjoner LagerForsendelse er en svært viktig prosess, og hvis man ikke tar hensyn til dette, kan varene gå tapt eller bli skadet. Derfor er det nødvendig å sørge for at emballasjematerialene oppfyller standardene, at emballasjen er tett og solid, at utseendet er glatt, fuktsikker, støtsikker og slitesterk når man pakker stålkonstruksjoner for frakt. Spesielt for bulkvarer må det også demonteres og pakkes. I faktisk drift bør man være oppmerksom på standardisert drift og overholdelse av relevante forskrifter for å sikre trygg og stabil transport av varer.

SELSKAPSSTYRKE

Laget i Kina, førsteklasses service, banebrytende kvalitet, verdenskjent

1. Skalaeffekt: Selskapet vårt har en stor forsyningskjede og en stor stålfabrikk, og oppnår skalaeffekter innen transport og innkjøp, og blir et stålselskap som integrerer produksjon og tjenester.

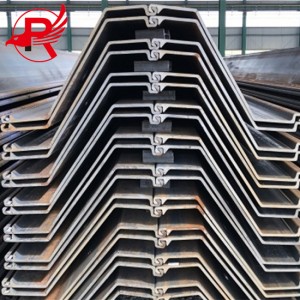

2. Produktmangfold: Produktmangfold, alt stål du ønsker kan kjøpes fra oss. Vi driver hovedsakelig med stålkonstruksjoner, stålskinner, stålspuntvegger, solcellebraketter, kanalstål, silisiumstålspoler og andre produkter, noe som gjør det mer fleksibelt. Velg ønsket produkttype for å dekke ulike behov.

3. Stabil forsyning: En mer stabil produksjonslinje og forsyningskjede kan gi en mer pålitelig forsyning. Dette er spesielt viktig for kjøpere som trenger store mengder stål.

4. Merkeinnflytelse: Ha høyere merkeinnflytelse og større marked

5. Service: Et stort stålselskap som integrerer tilpasning, transport og produksjon

6. Priskonkurransedyktighet: rimelig pris

*Send e-posten til[e-postbeskyttet]for å få et tilbud på prosjektene dine

KUNDER BESØKER